Suntrans Control™ is a high-tech. company with over 30 years of history, devoted to automation and energy AIoT. Suntrans Control™ innovates a series of Electrical Power IoT terminals and software systems wholly IP-owned, mostly in the energy management and control field.

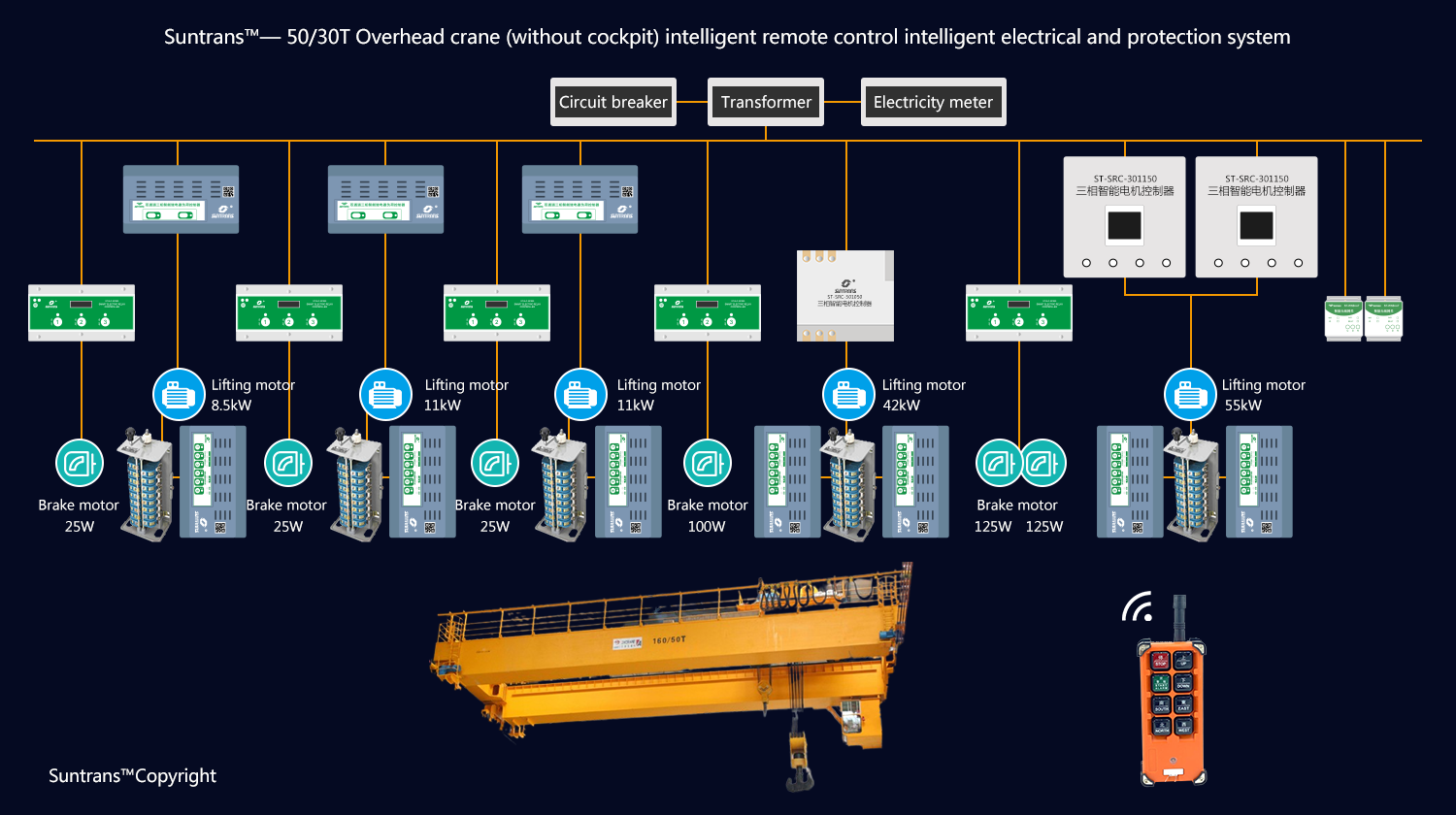

"Electrical Power Controller" is a seres of the most brilliant innovative products and systems among Suntrans Control™ IoT products. It is an great opportunity for the large-scale application of AIoT (Artificial Intelligence & Internet of Things) in industry & city construction. Since than, industrial measurement & control into smart equipment & system become much easier & much simplified in the era of new "Electrical Power Controller". The completion of intensive, smart and dynamic sublimation are the new symbol of AIoT. The process of AIoT since than become an implement & construction of the "Electrical Power Controller" application project only.

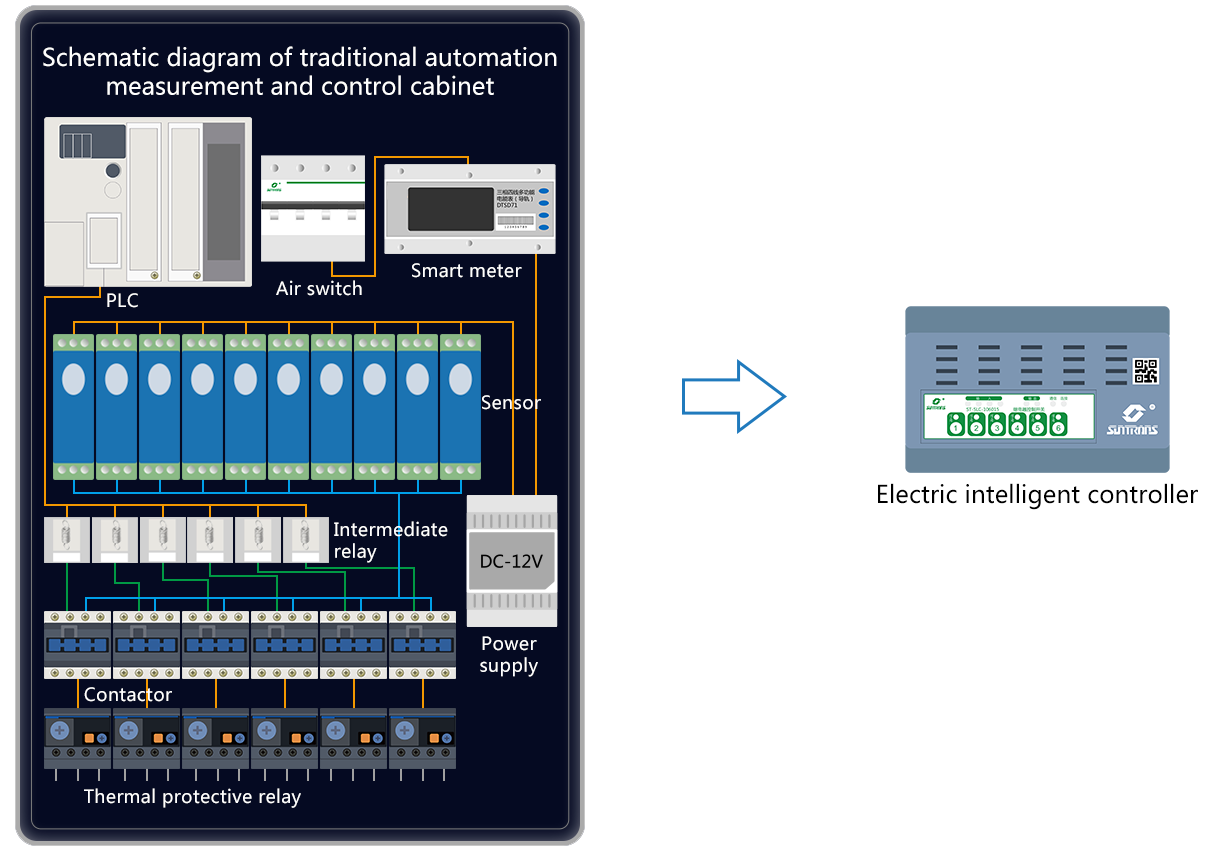

The figure above compares the traditional "integrated automatic control cabinet" and the new "Electrical power intelligent controller module"; it will surely make cross-generational progress. Its huge advantages and characteristics are that its core technology has achieved the power control of "AC zero-crossing-point" and has broken through the century-old bottleneck of "arc" and obtained high reliability, ultra-long-life "electrical type controller", several IoT terminal of the "Electrical Power Controller" shown in the figure below.

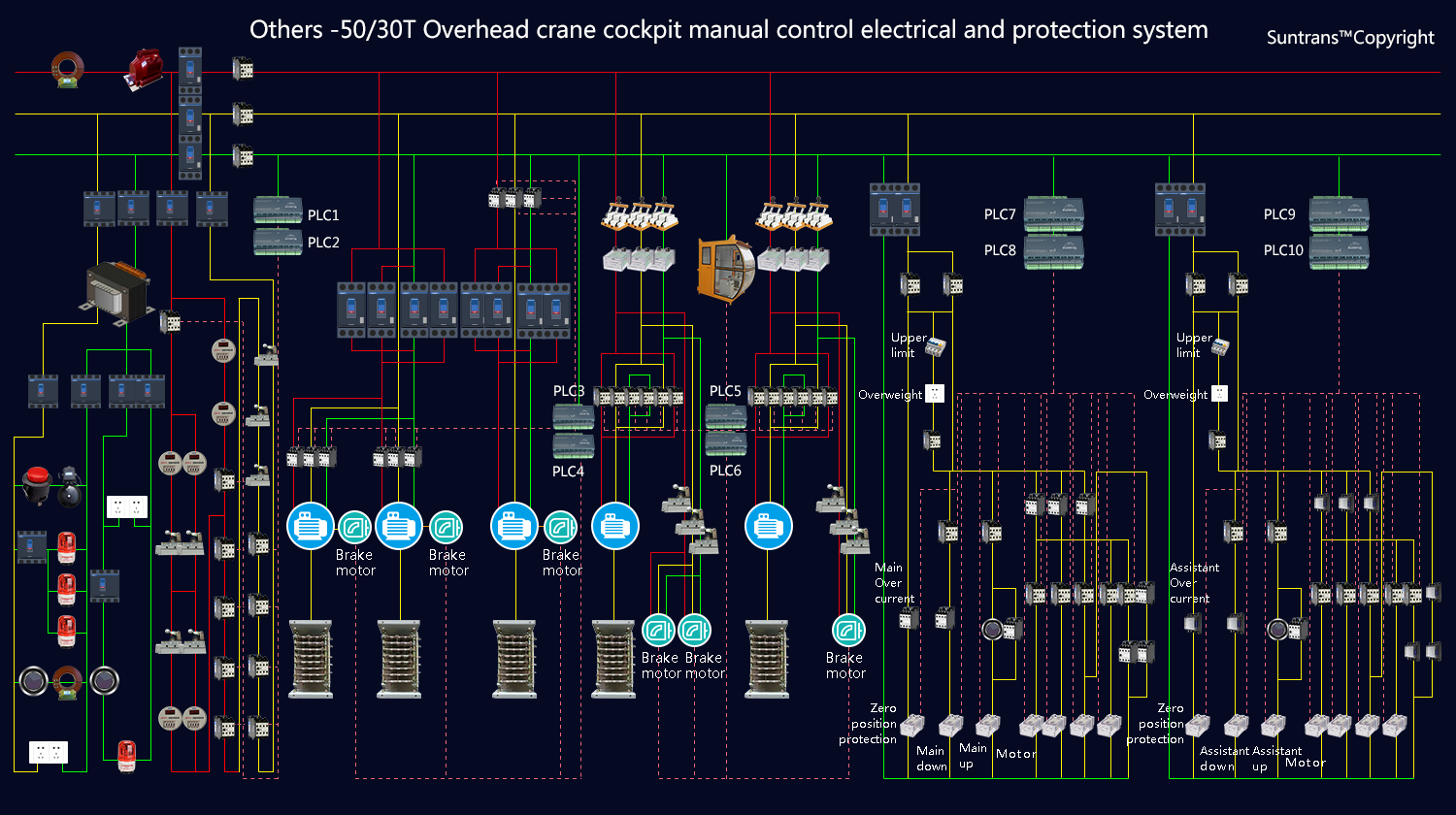

"Programmable Logical Controller" is commonly known as PLC, and "Distributed Control System" is known as DCS. It has been "vindicated" in automation in the past few decades. It is the most successful automation equipment in the era of automation. The advantages and historical contributions of PLC and DCS systems are not elaborated here. In the age of digital twins and the digital world, the shortcomings of PLC and DCS deserve great attention:

01 Electronic products: high requirements for the use environment, non-industrial or 3C electrical compulsory certification products;

02 High energy consumption: PLC or DCS itself consumes much energy, ranging from dozens of watts to thousands of watts;

03 A large number of cable joint integration and a vast engineering wiring is required, such as the measurement and control wiring between I/O and much-integrated equipment that need to be laid, drive intermediate relay wiring, measurement transformer wiring, sensor input wiring, instrument input wiring, etc., large quantity, large wiring workload, significant probability of abnormal occurrence, considerable electromagnetic introduction interference, complex maintenance;

04 Large energy consumption: PLC or DCS itself is power-consuming equipment, and the resulting measurement and control system and other integrated equipment also form the problem of high energy consumption of the measurement and control system, such as intermediate relays, AC contactors, frequency converters, etc., are all high energy consumption measurement and control equipment;

05 Large space: PLC or DCS often requires an ample control cabinet installation space, many electronic and power devices, and link cable integration to realise the automation function. These electronic control cabinets need a specific environment to operate safely, and many scenarios require a unique air-conditioning room guarantee;

06 Application environment constraints: PLC particular DCS often do not adapt to the industrial environment and cannot resist kinds of electromagnetic interference in the industrial environment, "high temperature, high humidity and high salt" They are electronic equipment; therefore, it is more challenging to resist overvoltage, counter-overvoltage, power surge, and is harsh on the electromagnetic operating environment;

07 A series of instruments are required: due to the constraint on the number of interface I/O of DCS itself usually requires a large number of industrial devices, sensors, etc., based on low-speed fieldbus to complete the measurement and control;

08 PLC, especially DCS integration, has very high requirements for the quality of relevant technical personnel, and the professionally trained industrial processes must, meantime, understand PLC or DCS programming. Skilled people who complete the system program are always not only dealing with the enormous workload of on-site debugging but testifying a much longer time to confirm the reliability and correlativity. When the logical relationship is complex, it often requires a large number of auxiliary relays and auxiliary controllers to complete the relevant logic and judgment. If you want the system can perceive the control object, it will be much more complicated and challenging to achieve;

09 Embedded programs, the programming and logical thinking ability of PLC's T-type diagrams require high requirements for operation and maintenance engineers, which is difficult to handle;

10 The operation and maintenance costs and difficulties are high. In case of failure, the highly professional technical personnel are a must required to troubleshoot the problem, which affects both labour hood and the industry productivity;

11 In the Big Data collection, analysis and control process, these systems' data refresh time and closed-loop control time have become bottlenecks. The software system of the cloud platform is also subject to the Fieldbus data acquisition cycle, resulting in the slow data refresh speed of the system, which often takes 10 seconds or more, and cannot achieve the current requirements. The "mirror" mechanism of the industrial design of "digital China" and "digital twin" is also challenging to realise AIoT.

Suntrans Control™ leads the Electric Power IoT; vital power intelligence innovatively develops and launches a high-performance series of the "Electrical Power Controller", which significantly simplifies the structural system of the industrial AIoT, promotes the electronic complex control system of discrete component integration, and replaces the era of high reliability "Electrical Power Controller". Technical parameters and indicators include control from project establishment to productisation and large-scale mature application.

It has taken 17 years for Suntrans Control™ to make the "Electrical Power Controller" in continuous exploration and truth-seeking. It has conquered and successfully commercialised the "AC zero-crossing-point, arc-free controller" technology and "DC arc-free control controller" technology. Especially the "Electrical Power Controller" is the unique controller which has passed the CCC & CE (Electrical Compulsory Certification) and has also been verified by hundreds of project applications since 2013.

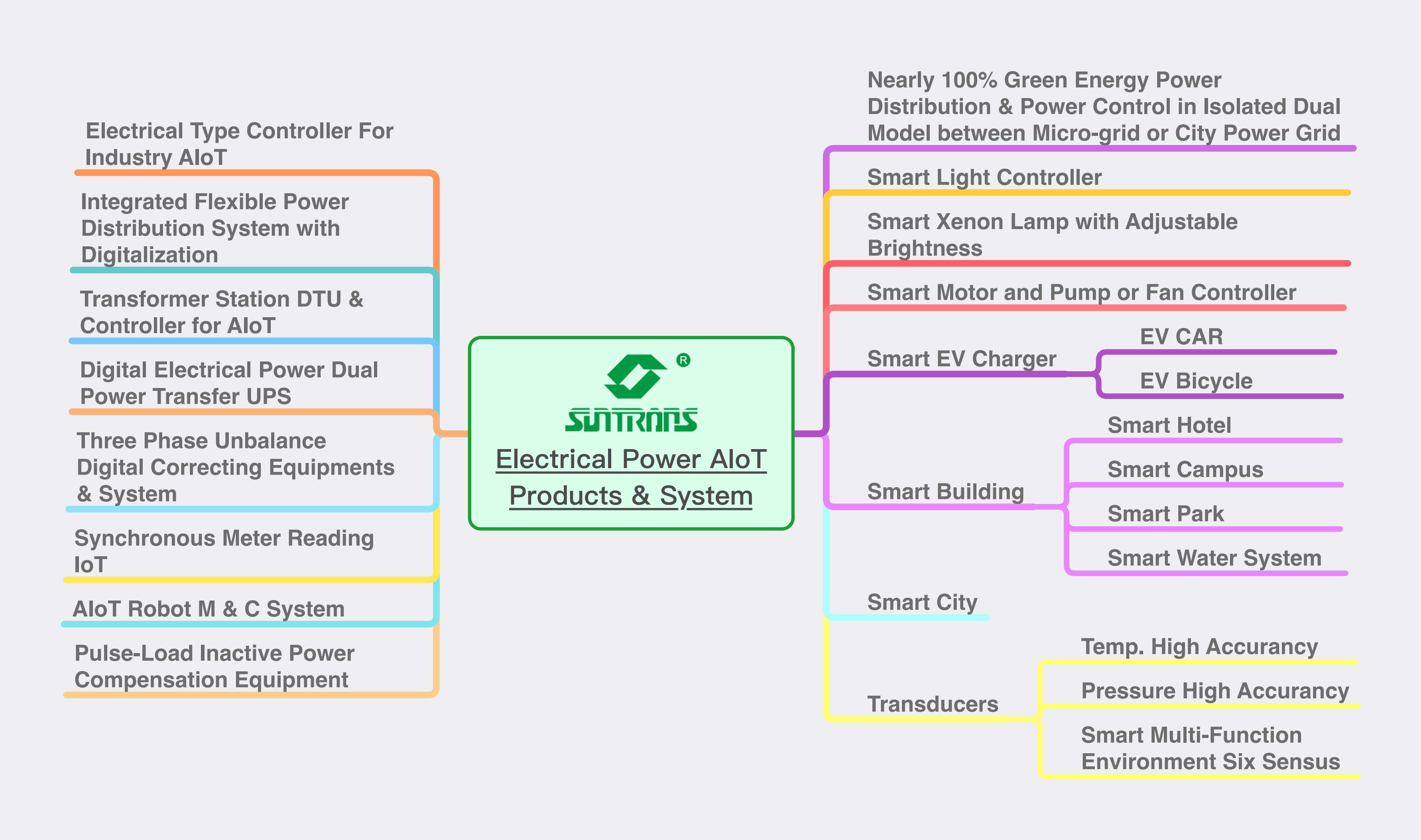

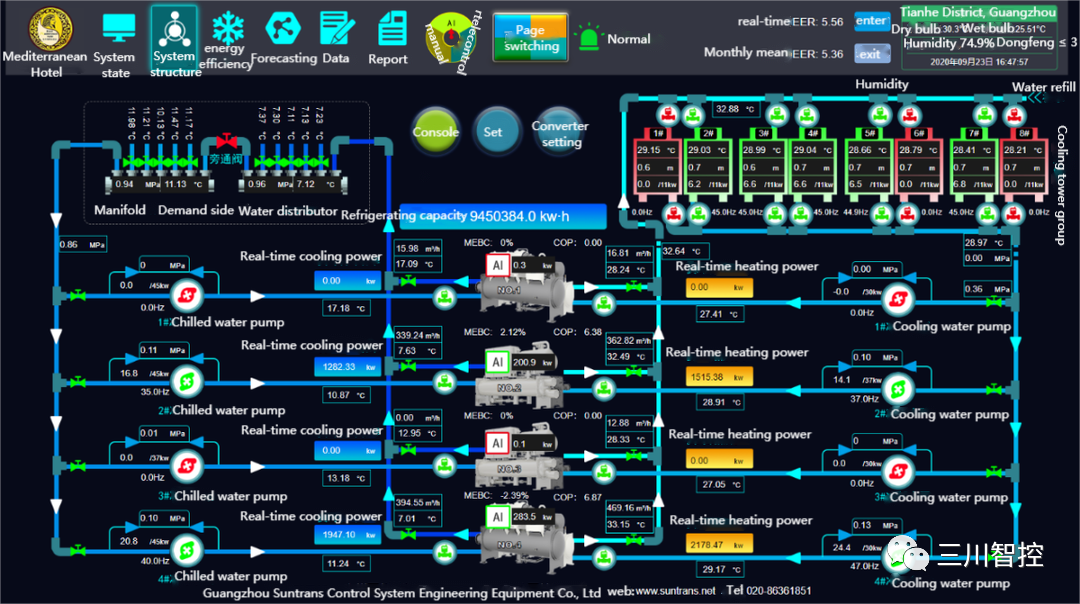

"Electrical Power Controller" realise high reliability, security and direct power output control characteristics. It synchronously constructs the advanced "AIoT terminal "direct echoes the "SuntransPlat", the energy management and control cloud platform. After the running-in and iteration of more than 100 practical application cases, Suntrans Control™ launch a new generation of "Industrial AIoT" series products based on the "Electrical Power Controller": it is named as ECO-Suntrans, it is suitable for the applications in the following AIoT scenarios:

01 Implement the construction of an "Integrated-flexible-intelligent power distribution system" or so-called ADR as well as VPP, suitable for power distribution in any scenario where digitalisation and safety are needed;

02 AIoT system for industrial equipment;

04 The construction of the ultimate energy-saving AIoT system of multi-objective, multi-task robust nonlinear processes, such as air-conditioning, thermal design, smelting system, and oil exploration equipment optimising upgrade;

05 High-reliability automation and intelligence of special engineering vehicles;

The "Electrical Power Controller" will lead the "Electrical Internet of Things", navigation "industrial AIoT" for the widespread application of high-performance energy management and artificial intelligence in industry, city building & construction, transportation, railway, hospital, municipal, campus and other fields. The "Electrical Power Controller" makes significant contributions and becomes a sharp weapon to achieve carbon peak and neutrality. The vision of Suntrans Control™ is to cooperate with entrepreneurs from all walks of life, deeply promote innovative technologies and products, break through the bottleneck of various industries' artificial intelligent subjects in software and hardware, and become a powerful force leading the fields of power, control and industrial intelligence.

- 在线实时演示

- Suntrans Plat 能源“云平台”演示

- 产品文件中心

- PWA安装说明