Industrial Internet of Things shaping - The successful application of electric controllers in the field of cranes

Thanks for the support and wise choice of Chengdu Tianxiang Environment Co., LTD.!

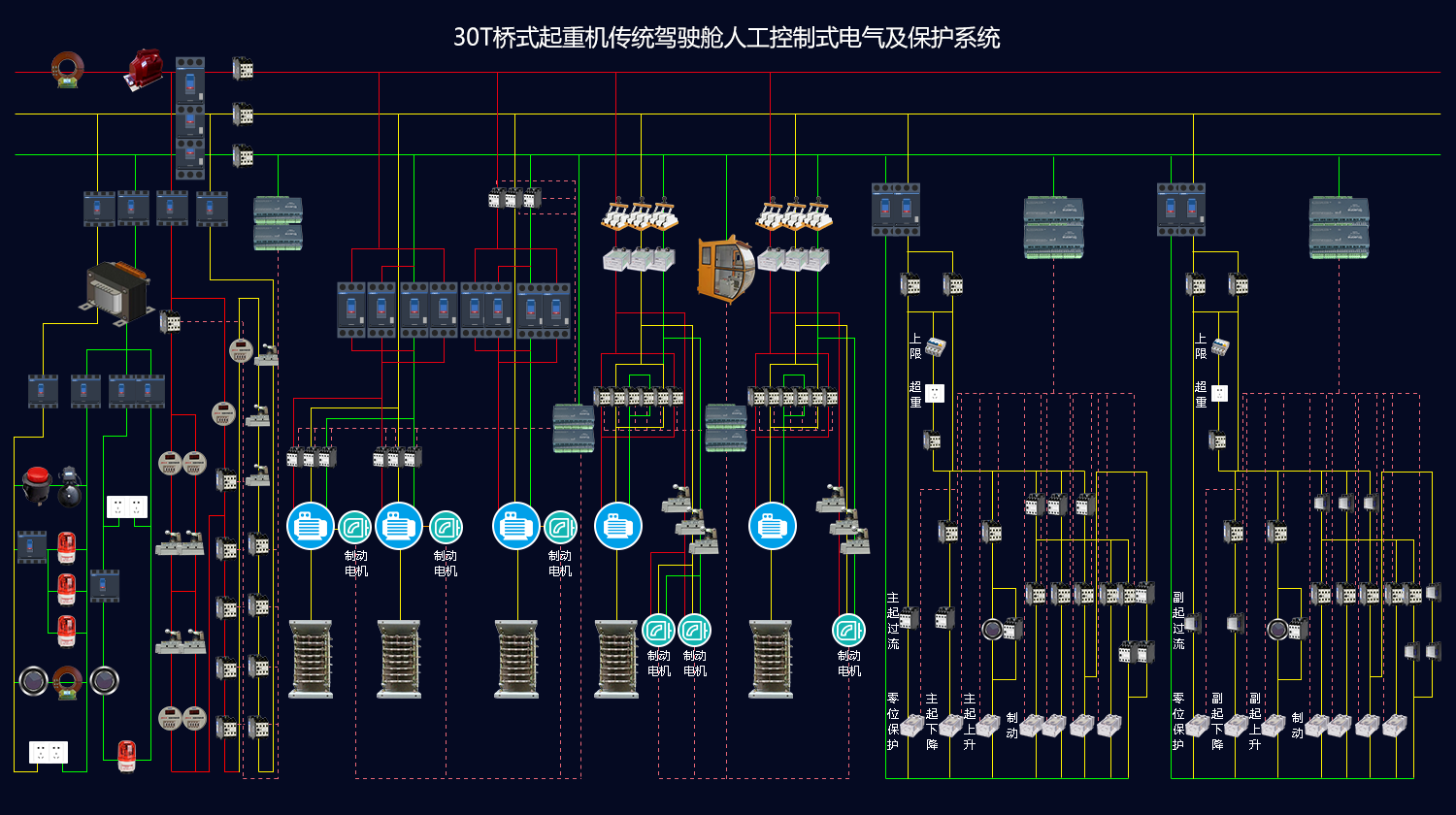

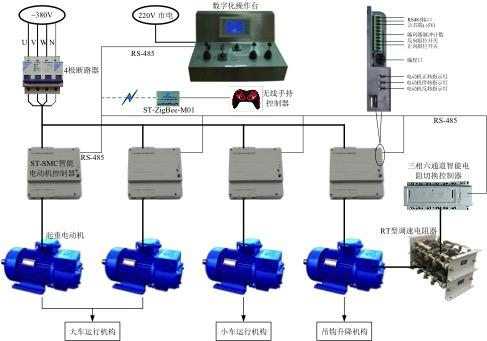

Crane is an important industrial equipment, its electrical safety monitoring, reliable operation and control, equipment health diagnosis, energy comprehensive control, are an important part of high performance crane.The traditional crane overcontrol system often requires multiple PLC programmable controllers, this electronic product as the core, through the control of intermediate relays, AC contactors and other a large number of discrete components, frame crane control system, as shown in the figure.

(Other electrical and control systems for 50T bridge cranes with 10 PLC frames (requiring manual field control of the cockpit))

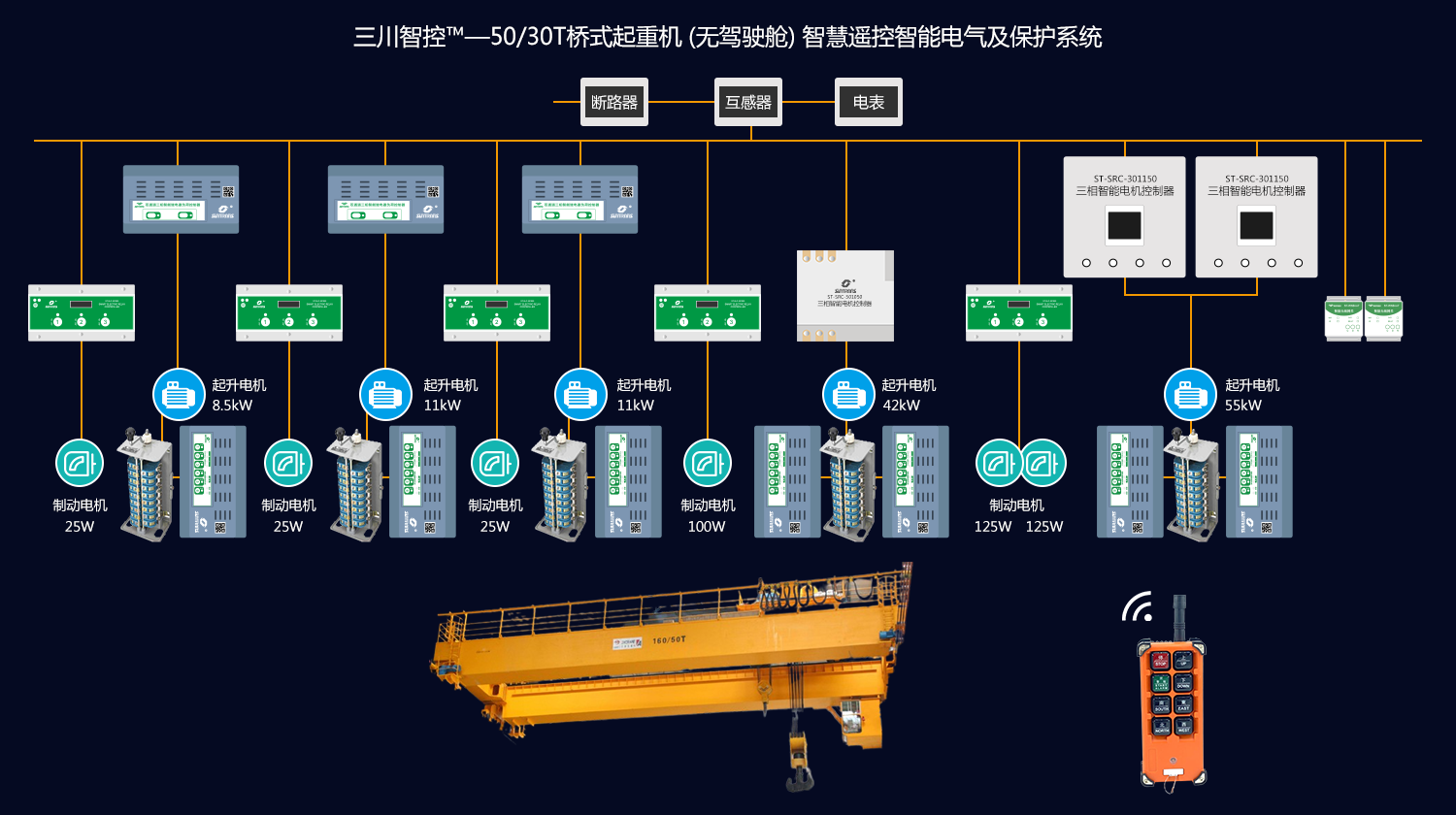

Sanchuan Smart Control ™ innovative electric power iot controller, intensive complete direct power controller control of electric drive equipment, such as crane series motor, greatly improve the crane control system:

1)Reliability, safety, handling;

2)Effectively ensure the dynamic equipment operating state diagnosis of the whole life cycle of the crane system;

3)The electric iot controller directly interfaces all the travel protection switches and second-level protection power off switches, and the protection crane without gap can realize prediction, early warning and prediction under abnormal circumstances.

4)When the first level protection is abnormal, high reliability cuts off the power supply of the corresponding circuit, and steps ensure the high safety of the crane equipment;

5)Accurately detect the data and status of every lifting motor, component and sensor, and directly incorporate the innovative electric Internet of Things without gaps;

6)Crane iot in one go, reduce more than 80% of the cable laying, reduce more than 80% of the space demand, reduce more than 50% of the weight of the equipment.

The first 50T/30T double crane bridge heavy lifting network control system of the equipment passed the acceptance in Chengdu Tianxiang Environmental Co., Ltd. on September 19, 2023, and was successfully put into application.For the smooth remote control experience of large equipment, the digital crane energy control system, the highly reliable AC zero crossing high-tech motor control technology and the high-performance intensive, lightweight crane control system, the operator is appreciated by the professional personnel without training can be convenient and safe operation. The system realizes the construction goals of digitization, intelligence, landing of Tianche, high safety and reliability, and intelligent cloud management and control of big data, and is also another successful application of Sanchuan Intelligent Control ™ high-performance power controller in industrial production.

(Suntrans™ professional team on-site installation of adaptive smart motor)

Cranes, also called cranes, are mainly used in power plants, water conservancy projects, construction, manufacturing, mining, aviation, shipping, metallurgy and other industries, is an important infrastructure in various industries.Electrical control is the core part of the crane, which mainly controls the operation and action of the whole crane to ensure stable and safe operation, so the controller in electrical control is very important.

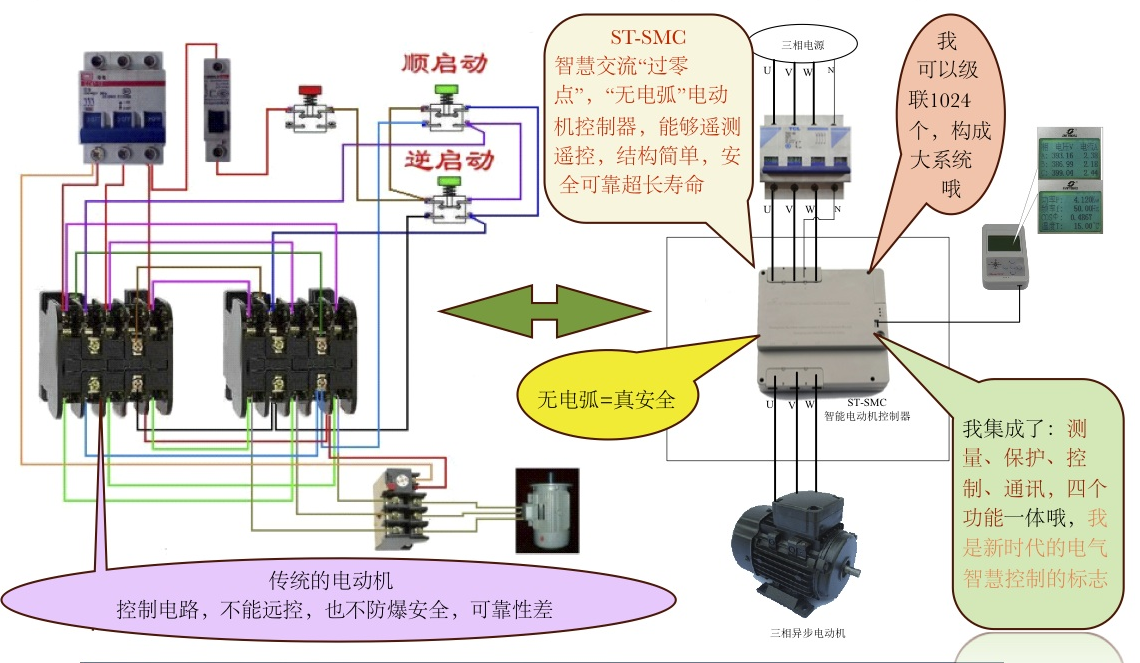

However, there are a series of problems in the traditional motor controller:1)The arc of breaking contactor has a serious influence on the life of electrical equipment;2)The impact on the motor is large, which affects the life of the motor;3)It has a great impact on the workshop power grid and affects the quality of the products;4)The control system is the direct manual operation of electrical equipment;5)Lack of power detection and energy consumption control;6)Lack of condition diagnosis of crane electrical equipment;7)Lack of crane equipment safety protection travel switch, power off protection switch process monitoring and so on.

In order to improve the safety, reliability, ease of operation and greatly extend the service life of the crane electrical control system, Suntrans™ patent develops a new product ST-SMC intelligent motor controller with no arc and zero overload:ST-SMC accurately measured and controlled at the moment of AC zero crossing, effectively suppressed the starting impulse current and the generation of arc when breaking, greatly extended the service life of the controller, and fundamentally met the needs of the motor to start frequently with large torque.At the same time, the controller is embedded with five digital functions of accurate measurement, accurate control, relay protection, reliable communication, and edge computing, so that the controller can directly echo the "cloud", and the industrial Internet of things can be built to realize the dynamic diagnosis of the health state of the motor and crane.

As a motor controller, the electric type controller can automatically put the motor rotor current limiting resistor combination at the start, so that the motor starts smoothly, moderate speed regulation, so that the motor works normally according to the required speed, so that the motor starts smoothly, reliable and long life.

When the current is broken at zero, ST-SMC is no longer subjected to the burning of the tension arc on the contactor contact, and the intelligent controller cuts the load when the AC current flows through the zero point, so that the motor stops smoothly, and the contactor and the motor will greatly extend the life.

ST-SMC has a powerful digital, big data, edge computing capabilities under the care of the motor state analysis function. With Suntrans™ professional "SuntransPlat cloud platform", ST-SMC has the ability to dynamically monitor crane and motor health status online, effectively realize any abnormal (such as: oil shortage, bearing anomaly, shaft anomaly, rotor anomaly, stator anomaly, etc.) online identification, intelligent operation and maintenance, prediction, early warning and forecast.

Application of ST-SMC in crane control

The traditional crane control mode is centralized control mode, and all power cables and control cables must pass through the power control box and operation console of the control center.A large number of cables, not only complex wiring, electrical safety concerns, but also greatly reduce the reliability of the system, equipment status diagnosis is often missing, or need to be constructed, difficult, extremely high cost, accurate reliability is poor.

ST-SMC electric iot controller, the use of high-performance AIoT technology system, self-lifting makes the entire crane system, become the Internet of Things terminal, power cable laying demand halved, measurement and control cable consumption reduced by 80%, but also has the following 6 features:

✷ Greatly improve safety, reliability, long life;

✷ Digital measurement and control and Internet of Things construction synchronous realization, economic benefits;

✷ Intelligent state diagnosis + active operation and maintenance;

✷ Operation digitalization, App, mobile;

✷ Measurement, protection, control, communication, PLC intensive light weight;

✷ To realize the synchronous AIoT transparent control of massive motor and crane groups;

(Traditional contactor control motor system vs intelligent motor control device)

-

Distributed controller system structure, simple measurement and control system, super edge computing

-

Convenient operation, wireless, bus, mobile control

-

Modular structure, intelligent maintenance, abnormal prediction and early warning

-

Zero overdrive motor control, safety and reliability greatly guaranteed

-

The impact on power supply equipment, workshop grid and lifting equipment is minimal

-

Measurement, protection, control, communication integration, frame crane group "cloud" management and control

-

The safety guarantee of operation is improved and accident recall can be realized

The successful application and stable operation of ST-SMC intelligent integrated motor controller in the crane of Chengdu Tianxiang Environmental Co., Ltd. greatly improves the stability and safety of the crane control system, and fully proves the electric iot controller of Suntrans™.A large number of electric iot controllers are used in industrial sites, replacing electronic controller PLC has far-reaching significance, and it is a preferred product that greatly improves the reliability, convenience and adaptability of industrial intelligent systems. It is also the best upgraded product that holds the "heart" of industry, construction and industry - "controller" in China's own hands, and it is also the most powerful equipment for leapfrog development in the controller field.

Suntrans™ has been committed to the "power Internet of Things, strong electric intelligence" for 30 years, and has innovated a full range of technologies and products in the field of AIoT smart energy management and control based on smart power distribution technology and power controller.The company has but not limited to: AC zero crossing technology, no arc intelligent controller, dual power UPS intelligent switching controller, "overall flexible intelligent power distribution system", "SuntransPLat/IoT cloud platform", electromagnetic coupling intelligent thermal unit, electromagnetic coupling intelligent thermal drying series of advanced products and solutions.The company continues to deepen its efforts in smart city, smart factory, smart building, smart hospital, smart campus, smart water and other fields, and provides digital, low-carbon, energy-saving, and smart services.More than 200 demonstration large-scale projects have been completed.A large number of cases, long-term actual operation and maintenance practice has proved that Suntrans™ solution has the most intensive, the most secure, the most economical and a three-dimensional, digital system.

- 在线实时演示

- Suntrans Plat 能源“云平台”演示

- 产品文件中心

- PWA安装说明